Description

Biofuels are one of the best candidates to support the energetic transition and reduce the current high dependence on conventional oil-based fuels. Control mechanisms are needed to guarantee the sustainability of energy crops and great advances in R&D in the biomass produced, whose role will be crucial in the next energy model in the medium-long term. Therefore, the current devices to mitigate the effects and the greenhouse gas emissions themselves must decrease with new anti-pollution systems.

The significant potential of the ozone injection technique as an exhaust gas purification system and fouling removal mechanism is the basis for the development of this project.

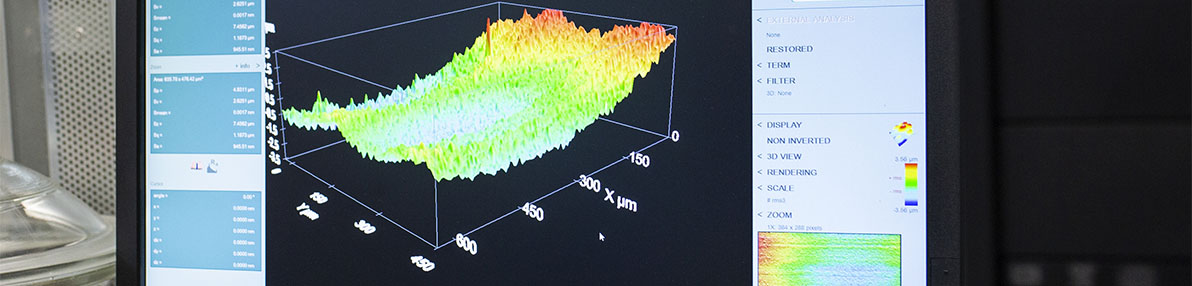

For this, the performance of exhaust gas post-treatment systems (EGR coolers) and the variation of the physical and chemical properties of the deposit before and after ozone regeneration have been evaluated. The results of this investigation have revealed that these systems can be regenerated under different ozone concentrations achieving the best performance when the gas flow temperature is slightly above 150°C. It has been shown that ozone injection can reduce the content of soluble organic fraction (SOF) of the fouling layer significantly as well as the combustion temperature of the soot is reduced, which implies an improvement in the reactivity of the deposit.

State of the art

In the last two decades and alerted by the scientific community, the public opinion of the developed and developing countries became aware of the big threats that the gas emissions associated to the industrial development carried out in these countries exert on the atmosphere. Since the Montreal Protocol treaty in 1987, the damage on the ozone layer due to the emission of fully or partially halogenated hydrocarbons (CFCs and HCFCs) has been drastically reduced by the development and use of the substitutive PFCs and HFCs together with new environmental-friendly refrigerants, aerosols and fire retardants. The side effect in the use of this substitutive gases is the additional greenhouse effect that these gases have in our planet, yielding to the current problem with the global rise of Earth’s temperature. As a consequence, the Kyoto protocol and subsequent United Nation treaties like the Paris agreement, focused on policies to reduce the emission of not only PFCs and HFCs and other fluorinated gases but also nitrous oxides, methane and CO2 as the big contributor to the global warming effect. In high industrialized countries as EU-27 or USA more than 80% of the emissions (CO2 equivalent) of greenhouse gas (GHG) in 2018 corresponds to CO2, followed by methane (10%) and nitrous oxides (around 6% – 7%).

Though the targeted levels of GHG for 2020 have been fulfilled as a whole, the European Environment Agency is alerting that there is a problem with CO2 emissions in the transport sector. Around a 30% of total CO2 emissions in Europe are due to transport and road transportation is the only responsible of nearly a 72% of the previous figure. In the last five years, there was an upturn in the exhausted CO2 emissions after a continuous reduction year after year. For instance, from 2016 to 2019, the CO2 emissions level for new passenger cars that represent the 60.7% of the total road emissions, has risen from 118 to 122.4 g CO2/km. The target for 2020 established in 95 g CO2/km, will clearly not be achieved and what is more, the goal for the year 2030 has been fixed in 59.4 g CO2/km

Therefore, great improvements with a high degree of innovation have to been developed on the current energetic model of the transport sector and the automotive industry. In that sense and with the CO2 emissions as the enemy number one, the next long-term EU strategy in its environmental policies for the next 30 years , will be focused on being climate-neutral by the end of 2050, yielding to a prosperous, modern, and competitive economy with net-zero GHG emissions.

Due to the increasingly stringent regulations of gaseous pollutant emitted by internal combustion engines have come into force in recent years, the automotive manufacturers and shipping companies, and all the industry in general is facing unprecedented pressure to take measures to abate multiple kinds of pollutant gases produced by internal combustion engines. In this area, the exhaust gas recirculation (EGR) system, together with other technologies such as the diesel oxidation catalyst (DOC), the lean NOx trap (LNT) or the selective catalytic reduction (SCR), has proven to be useful means of reducing the formation of nitrogen oxides (NOx) emissions produce by combustion internal engines . This technique works by recirculating a portion of the engine’s exhaust gas back to the cylinders, lowering the combustion temperature and, hence, limiting the generation of NOx. The EGR cooler, a compact heat exchanger that is a key component of the EGR technology, is in charge of reducing the exhaust gas temperature prior to entering the combustion chamber, which increases the effectiveness of this technique.

One of the major problems encountered in the EGR system is the fouling of the heat exchanger surfaces. The particulate matter and the volatile species derived from the combustion of fossil fuels lead to the formation of highly porous deposits that can cause the degradation of the heat transfer performance of the device in the range of 20%-30%. The accumulation of this unwanted material adversely affects the control of the EGR technique, altering the normal functioning of this device. In order to find a solution to the fouling phenomenon that occurs inside the EGR system, recent studies have focused on the analysis of non-thermal plasma injection (NTPI) as a potential method for both exhaust gas purification and fouling removal mechanism. The reaction between the reactive species produced by the NTP reactor, such as high-energy electrons, ions, reactive free radicals, excited molecules and ozone (O3), and the unburned hydrocarbons carbonaceous compounds (presented in the exhaust gas as a volatile and soot particles) can activate complex chemical reactions, that lead to a rapid oxidation . On this issue, it has been observed that different studies have analysed the deposit removal and the effectiveness improvement of the EGR cooler after being exposed to different ozone flows produce by non-thermal plasma injection techniques, such as those carried out by Chen et al., Shi et al. and Li et al. The main objective of these researches is to evaluate the EGR cooler performance and the variation of the physical and chemical properties of the deposit before and after the regeneration. In these studies, the EGR cooler is evaluated ex-situ employing an experimental layout. The NTP generator is dielectric barrier discharge (DBD) type with co-axial cylinder structure. The concentration of the different gas species is determined using gas analysis devices and the temperature of the entire line of the experimental setup is monitored employing temperature control systems. The results of this research have revealed that EGR coolers can be regenerated by both air-fed NTP and oxygen-fed NTP under different ozone concentrations at a wide temperature range of 18°C to 300°C, achieving the best performance when the temperature of the gas flow is slightly above 150°C. The thermo-gravimetric analysis of the fouling layer has proved that ozone injection can reduce the content of soluble organic fraction (SOF) in deposit specimen from 36.5% to 18.3%.

In addition, it has been demonstrated that, after treatment by ozone exposure, soot combustion temperature is reduced, indicating that this regenerative technique has a positive effect on improvement of the deposit reactivity. These studies have unanimously concluded that this after-treatment technique can contribute to the fouling mitigation, indicating that ozone injection is a potentially promising technique to reduce fouling in EGR coolers.

In addition to the EGR system, the use of the ozone injection as a fouling mitigation technique has also been tested in other applications, such as the diesel particulate filter (DPF) regeneration or the purification of exhaust gas flows produced by diesel engines.

On the one hand, DPF is considered one of the most effective means to reduce diesel particulate matter emissions, but this system can become blocked due to long-term particle deposition, causing the deterioration of the engine operation . For this reason, several studies have focused on DPF regeneration technologies using an ozone injection or the indirect plasma method. These research works, such as those carried out by Kuwahara et. al. , Pu et al. and Okubo et al. , have examined the DPF regeneration process assisted by nonthermal-plasma-induced ozone injection, employing both real and pilot-scale experimental facilities. On the other hand, ozone injection strategies have been used in exhaust gas purification systems, in order to reduce the particulate matter and nitrogen oxides (i.e., NO and NO2) and hydrocarbon emissions produced by internal combustion engines. Several research, such as the studies carried out by Madhukar and Rajanikanth , Yoshioka et al. and Gu et al. , have analysed the pollutant mitigation potential of ozone when it is injected inside the exhaust gas stream. Employing different experimental setups, they have evaluated the emissions concentration and the size distribution of the particulate matter downstream the ozone injection, reporting that this technique can minimize the hydrocarbon content and NOx emissions under different operating conditions. They have also revealed that ozone injection can drastically reduce both the concentration of the particles with diameters ranging from 25.5 to 124.1 nm and the proportion of volatile material of the particulate matter.

In addition, it has been detected that, to improve the removal efficiency of NOx and SO2 of the exhaust gas streams produced by marine diesel engines, some studies have combined the ozone injection method with wet scrubbing processes, such as those conducted by Zhou et al. and Han et al. This technique combines the ozone injection method in the exhaust gas flow with a wet scrubbing system, which employs an alkaline absorption solution (NaOH or CO(NH2)2). Results obtained by applying this experiment procedure have revealed that this combined approach reduces the ozone thermal decomposition, achieving a NOx removal efficiency of 63.4% and a complete removal of SO2 at the same time.

The high efficiency of this techniques and its long-term industrial development potential have served as the focal point for the emergence of new patents. For this reason, original equipment manufacturers (OEMs) of the automotive sector have patented some of the techniques referred above, reflecting the fact that they can become appropriates technologies to reduce the pollutant gases produced by internal combustion engines an the interest of the sector. Following is a summary of the most important aspects of these patents:

| Patent nº | Title | Applicant | Field of application |

|---|---|---|---|

| US 8051643 | Exhaust gas purification system utilizing ozone | Toyota Motor Corporation | DPF regeneration |

| EP 1026373 | Device for purifying the exhaust gas from an internal combustion engine | Volkswagen Group | Gas purification + filter regeneration |

| WO 2008/053105 | Exhaust line of a diesel engine and method of regenerating a particulate filter | Renault | DPF regeneration |

| WO 2007/142355 | Device for purification of exhaust gas | Toyota Motor Corporation | Gas purification + filter regeneration |

Analysis of these patents shows that all the methodologies proposed have been conceived and developed mainly for the mitigation of fouling inside diesel particulate filters. All have been designed as an aftertreatment devise that is focused on promote the regeneration of the particulate filter through the removal or incineration of the deposit that grows inside the complex and intricate structure of the DPF, thereby ignoring its use in other exhaust devices that are also affected by the fouling phenomenon, such as the EGR system or the SCR system. This highlights the need for new anti-fouling and purification techniques with wider development goals, that offer a comprehensive and durable solution and that provides a sophisticated strategy that contributes to the reduction of the pollutant emissions inside the entire exhaust gas line.

Objectives

The main objective of this application is to exploit the significant potential of the ozone injection technique as exhaust gas purification system and fouling removal mechanism. On the basis of the results achieved during the previous study, this project aims to develop this technique making innovative efforts in order to obtain a system that can be properly implemented in existing internal combustion engines, effectively leading to the reduction of the emissions of pollutant derived from the combustion of fossil fuels. Within this framework, it is intended to move from an experimental proof of concept (TRL3), which was developed in the previous action, to a technology demonstrated in relevant and operational environments (TRL6-7).

To achieve this objective is required to establish the optimal operating conditions of this new technique, indicate the implementation modes and the management tools of the system, as well as determine the operating strategy of this methodology. At the same time there is a need to analyse, verify and select the physical components and devices that meet the wide-ranging of performance demands, and that guarantee the proper functioning of this technique. Consequently, the new system shall comply with the following specifications:

- Effectiveness. The system must have a high cleaning and purification efficiency, particularly at low and medium engine loads, ensuring that its operation does not alter the overall efficiency of the engine. Furthermore, all the modes of operation of this system must guarantee a reduction of the pollutant emissions, contributing to reduce the gaseous pollutants generated by internal combustion engines.

- Durability. The system must guarantee its normal functioning without the replacement of any component or major interruption for at least 5 years, demonstrating that it can operates correctly over a long period of time. In addition, the materials used must be appropriate to work under high ozone concentrations, showing high durability under a wide range of operating conditions.

- Compactness. The devices must be as compact as possible so they can be coupled in existing facilities, in such a way as to avoid major changes in other systems.

- Robustness and security. The system must meet the safety and quality standards of products of similar characteristics. Moreover, due to the presence of ozone and other reactive species, this technology must comply with the specific requirements that ensure a controlled and safe environment.

- Low maintenance. It must ensure that both the user and the marketer do not have to take action except for scheduled maintenance.

- Manufacturability. The design of this system must be oriented towards technical feasibility, that guarantees the mass production of the devices in compliance with the current manufacturing standards. In addition, this technology must be a competitive application, whose implemented components must be economically viable.

With regard to the aspects of the development activities of the research team, this project aims to stablish innovation-friendly culture, that creates an environment favourable to innovation and technological process, in which research team feels comfortable sharing ideas and discussing the emerging innovative solutions. This project aims to train the research team in technical issues and new methods of entrepreneurship, innovation and technology transfer, that enhances their creative ability, their capacity for innovation and their professional skills. For this reason, it is intended both to enhance coordination and the potential of the research team, strengthening the synergy among the various components of the group, and to plan continuous training programmes that promote the team entrepreneurial capacity.